Goggles have been used at least since the American Civil War by Artillerymen and then Railway Engineers. Garnet Wolseley was an observer during that conflict and may have been instrumental in their introduction into the British Army for the Sudan campaigns of 1882-1885. However this article is concerned with “The Newbold Type” used by the British, Americans, Japanese and others.

Goggles have been used at least since the American Civil War by Artillerymen and then Railway Engineers. Garnet Wolseley was an observer during that conflict and may have been instrumental in their introduction into the British Army for the Sudan campaigns of 1882-1885. However this article is concerned with “The Newbold Type” used by the British, Americans, Japanese and others.

British – 1916 Triplex, RFC/RAF MkI & MkII and WWII Army ‘General Purpose’;

USA – 1918 ‘Resistal’s’ or WWII M38;

Japanese – early Navy Aviator and WWII Tank Goggle;

&etc.

or

‘The Newbold Type’

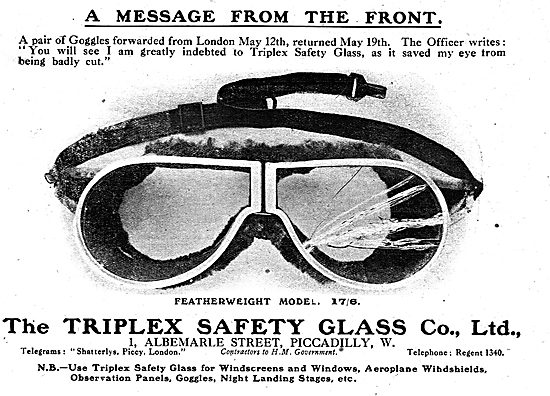

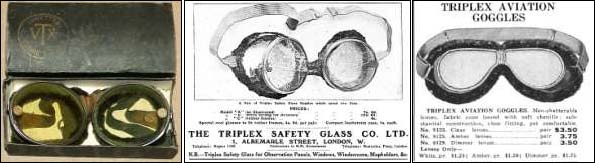

Figure 1. Mid-1916 Triplex advertisement for Newbold’s design. Already incorporating Salt’s frame improvement.

This goggle type was extremely popular from mid-WWI and during the first half of the 20th Century; versions were still on sale until at least the 1960’s. Because of their strength and simplicity many manufactures emulated the design and at least three major nations selected versions as official military gear; all three countries originally adopted them as aviation items, and then relegated them to land transport goggles in the 1930’s. Because of the large number of versions made, both as government contract items and commercial pairs sold to the public, there is much confusion about the origins and history of the type. Today in the UK any goggle of this shape is often called ‘MkII‘s’; even those not produced for the Royal Flying Corps/Royal Air Force (RFC/RAF). In the United States they are usually referred to as ‘Resistal type’ even though they were originally copied from the RFC MkI’s; and Resistal made several other styles. Also routinely called U.S. M38 or M1938 type, even if they are fur-lined commercial items, pre-1938 or produced after the U.S. military contract lapsed with the introduction of the Polaroid M44/B8. The Imperial Japanese Navy aviation variant is often called the ‘old type’ or ‘pre-eagle (or cats) eye’; Japanese ‘Tank Glasses’ from 1930 to 1945 were also a version of the design. They are also generally referred to as ‘pear shaped’, ‘teardrop shaped’, ‘comma shaped’, ‘hinged goggles’, or ‘General Purpose’ etc. Historically they were called the ‘improved type of Triplex goggles’ (1917, see U.S. versions discussion) or the ‘Triplex type’ (1929, see section on Japanese versions), but complexities in that trade name’s history and product line leads to confusion. Often an unidentified pair will be called one of the above, with the choice of epithet being more indicative of an author’s personal interest than the actual origin of the item.

Perhaps generically we should call them the ‘Newbold Type’?

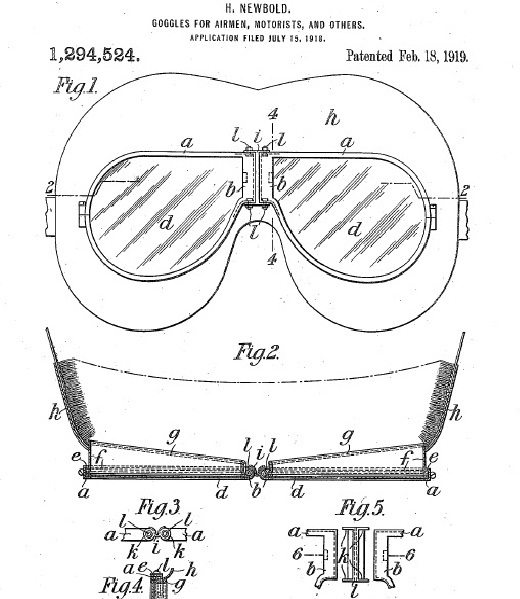

Figure 2. Harry Newbold designed these goggles in or before 1916. British (116597) and French (490971) patents were lodged 2nd Aug 1917. Shown here are near identical U.S. patent drawings lodged 15th Jul 1918. Newbold had also patented a double hinge pin design in 1904 (US775,881) and in 1900, with James Aitchinson, actually invented the ubiquitous wire sprung cup (Pat. GB7263).

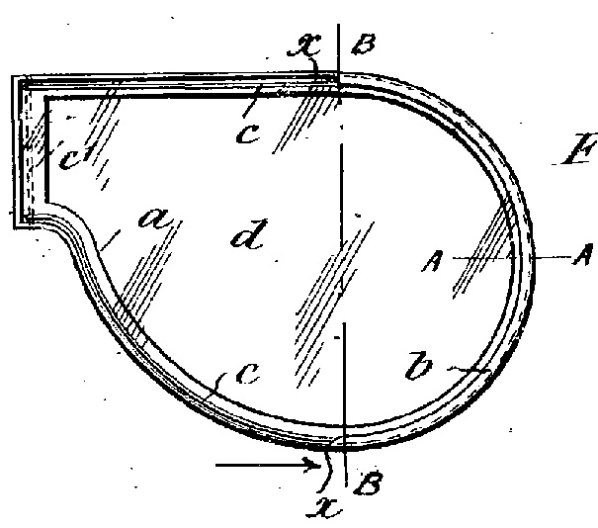

Figure 3. Detail of Albert Salt’s patent drawings ‘Improvements in and relating to Goggles for Airmen, Motorists and Others’ (Pat 127545) lodged with the British Patents Office 11th Mar.1919. His simplified solid frame must have followed the appearance of Newbold’s split frame design almost immediately as they appear on advertisements for the ‘Featherweight’ model as early as 1916.

Although hinged spectacles had been around since their invention (usually to aid storage rather than as an ergonomic measure) and goggles with single pin hinges had been available since at least 1890’s (e.g. 1895 version of The Lamb Eye Shield), Newbold’s 1904 and 1916 designs were the first to have double hinge pins enabling variable movement between the lenses giving some flexibility which allowed adjustment to the face, rather the stiff variable v-shape of single pin hinge versions.

Triplex, ‘Peeling Back the Layers’

As the origins of this goggle type are linked strongly with the name ‘Triplex’ perhaps an unravelling of that trade name’s early history is needed.

Laminated glass was originally developed almost simultaneously by a Briton and a Frenchman. An English solicitor, John C. Wood, after taking up driving and finding he needed protection from the elements, but hearing horror stories of injuries inflicted by broken plate glass produced an award winning laminated car windscreen in 1905; obtaining a British patent later that year (9972). Frenchman, Edouard Beneditus was unaware of Wood’s work and continued work on coated glass started by the company Le Carbone in 1902, he gained a French patent in 1909, and a British patent, 1911. Their inventions had various clear non-brittle membranes (e.g. cellulose, celluloid, xylonite, pyralin) self bonded or glued between two layers of glass as a sandwich. Originally Beneditus used gelatine and Wood canada balsam resin as the bonding agents. If the surface of the glass was struck and failed the non-brittle membrane would not shatter and the bonding material would keep the shattered glass safely attached to the membrane. Benedictus patented his development as ‘Triplex’, but Wood’s invention is also reported to have been sometimes called the same, so the earliest roots are confusing. Wood set up the ‘Safety Motor Screen Co.’, in 1906 producing and marketing laminated glass. Later in France, Beneditus formed the ‘Societe du Verre Triplex’ in 1911, also producing safety glass auto-products. With the eras cavalier attitude to safety, however, neither was a notable commercial success.

Announced in The Times 31st Oct, 1912 was the registration of the first British company actually called Triplex; ‘Triplex safety Glass Co. Ltd’ set up by Reginald Deplech; later described as a ‘pioneer British motorist’. This first British ‘Triplex’ had agreements with the French patent holders (note, gelatine is much cheaper and easier to handle than the more durable canada balsam); this London company, originally located in Willesden, was producing Triplex glass products from 1913 onwards.

The Triplex Safety Glass Co. Ltd, were soon trading from 1 Albemarle St, Piccadilly, London. As well as marketing ‘windscreens and windows, aeroplane windshields, observation panels and night landing stages’, they started to produce goggles at the start of, or just before WWI. Advertisements for their ‘Aero Motor’ goggle range, (models A, B & C; all typical Edwardian goggles) can be found in the press in early 1915 (see top three Fig. 4).

Figure 4. Pre-MkI RFC aviation goggles. Top two; brown rubber framed Edwardian style, common from at least 1910. Triplex produced versions as their ‘C’ series; in 1914-15 these were the commercially bought ‘RFC 1st Pattern Goggles’ and then became WWI army ‘General Purpose’. Centre right, round Triplex Aero-Motor goggle ‘A3’ a typical Edwardian wire framed design, also used by the RFC early in the War. Bottom two, are more robust War-time designs, the Goggle Mask is similar to the MkI, but has no hinge, making it a little flimsy. The bottom one is a similar un-hinged design, without mask, but has black rubber lens frames; said to be a RNAS (Royal Naval Air Service) design? (Note; WWI Triplex advertising confirms that the completely rubber framed goggles were their ‘C’ series and the round or oval wire sprung cups their ‘A’ series, post War the series nomenclature changed and the wire and cloth ‘A’s became ‘C’s. The ‘Compact leatherette case’ came as an extra, at 1 shilling each (1915)).

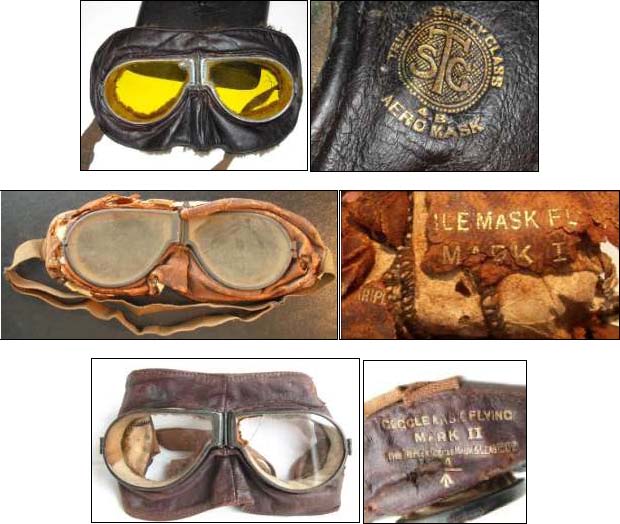

It seems the ‘Triplex, Goggle Mask and Lens Co., Ltd’, was set up separately from ‘Triplex Safety Glass Co. Ltd’ when the latter’s ‘A.B. Aero Mask’ was adopted by the British Government for the RFC in Dec. 1916 and mentioned in U.S. Government Special Regulations No.41 in Aug. 1917. It may have become apparent that the goggle side of the business warranted a separated company as mass production was needed, not just of thin optical quality laminated glass, but textiles, leather and metal work. The company became very lucrative and well known due to these and other Government contracts and the brand name itself became valuable; as post war corporate machinations would show.

Figure 5. Top, commercially available ‘Triplex A.B. Aeromask’, introduced in early 1916, note, produced by ‘Triplex Safety Glass’. Adopted by the RFC in December 1916 to become (middle) the ‘Goggle Mask Flying MkI’, and in 1918 with very subtle differences (bottom) the ‘Goggle Mask Flying MkII’, Note, both military items were produced by ‘Triplex, Goggle Mask and Lens Co., Ltd’; a subsidiary company set up by Triplex Safety Glass to deal with the Government contracts. All Goggle Masks were split frame models.

Figure 6. ‘Featherweights’, Left, very early, still with split frames. Centre, solid frame pair with ‘Yulo’ marked frames, in a Triplex case. Right, Post 1919 pair with Salt’s Patent no. on the frame. Note all have darker cloth than the later ubiquitous light grey British military production (Figs. 17 & 21).

The Triplex, Goggle Mask and Lens Co., Ltd, was registered in 1917, as noted in the ‘New Companies Registered’ section of Flight Magazine, 29th Nov. 1917 – ‘TRIPLEX GOGGLE MASK AND LENS CO., LTD. With Capital of £3,000, in £1 shares. Optical glass manufacturers, manufacturers of goggles and goggle masks (particularly those fitted with Triplex safety glass for the use of aviators), eye glasses, &c. Under agreement (a) with the Triplex Safety Glass Co., Ltd., and (b) with J. H. Bulford. First directors, R. G. M. Delpech and J. H. Bulford.’

It is interesting to notice that as well as Triplex’s founder, Delpech; J.H. Bulford was also party to the new company’s setting-up, becoming a principal director. Newbold & Bulford Ltd (est. 1796) was an old name in London optical and scientific lens and instrument business. It appears that Delpech may have involved members of this old ophthalmic family firm in setting up the optical side of the Triplex business. Harry Newbold, born into the profession, had been involved in designing and patenting protective goggles and spectacles since at least 1900.

Figure 7. From 1916 on First World War Triplex and/or RFC Mk I and Mk II goggles. All are ‘goggle masks’ apart from the two at top right which are ‘Featherweight’ pairs as in Fig. 1 & 6, split and solid frame respectively.

In 1920 British Glass Industries bought a large interest in the Triplex Safety Glass Co., and in 1922 it was taken over completely by another public company also calling itself Triplex. Yet again in 1923 the name ‘Triplex Safety Glass’ was taken over in Britain by the major glass maker Pilkington; they had shown interest in 1912 but negotiations with Societe du Verre Triplex had failed and Delpech had gained the patent use at that time. The new owners of Triplex Safety Glass Co. Ltd and the ‘old’ Triplex, Goggle Mask and Lens Co., Ltd went through the courts in 1921-23 in a ‘debenture’ case. This, and very low interim dividend payments by T.G.M.& L. to T.S.G. of a symbolic £100 in 1918, would suggest the original relationship was in the nature of a Gentleman’s agreement and that loan settlements and patent use demarcation etc were needed when the Triplex name and patent rights were being bought-out. Interestingly the name Triplex, Goggle Mask and Lens Co., Ltd seems to disappear from the historical record at this time.

In 1926 Armory Haskell bought the rights from the French patent holders to manufacture laminated glass in the United States, part financed by Henry Ford. Reginald Delpech had actually contacted Henry Ford after Ford had had an accident, recommending Triplex glass; which Ford then imported from England until Haskell’s U.S. production began. Thus creating ‘Triplex Safety Glass Co. of North America’. The U.S. Triplex company also produced a ‘Newbold’ like goggle around 1930, identifiable by having a single hinge pin, like a small protruding door hinge.

So as can be seen calling this design ‘Triplex goggles’ is fraught with problems not only due to the several Triplex companies operating over the years (e.g. Fig. 8), but also because ‘Triplex Safety Glass Co., Ltd’ made at least ten other styles of goggle, as well as spectacles and experimental military vizors. The patent name ‘Goggles for Airmen, Motorists and Others’ is unwieldy and never caught on.

Figure 8. Three different Triplex companies all producing goggles. Left, French ‘Societe du Verre Triplex’ goggles, early WWI. Centre,1915, one of at least 10 styles of goggle made by the British ‘Triplex Safety Glass Co. Ltd’. Right, 1931, a pair made by the ‘Triplex Safety Glass Co. of North America ’

Tentative WWI to 1930’s History and Discussion or ‘Facing the Keiser and Bridging the Atlantic’

So unambiguously the designer of this goggle type was Harry Newbold of the Triplex Safety Glass Co.Ltd, London, in or before 1916. They were on sale by May of that year (Fig. 1). Commercially called ‘The Featherweight’ in normal goggle configuration (for motoring or aviation), or the ‘Triplex AB Aero Mask’ when attached to a leather face mask (Fig. 5. top).

The RFC adopted the ‘Triplex AB Aero Mask’ as official flight gear in December 1916 and under Government contract it became the ‘MkI Goggle Mask’. Although the British military had previously bought and issued a couple of existing goggle types, the AB Aero mask was the first type to be specifically contracted and manufactured for the Government, and hence get a ‘Mark’ (Mk) number. In 1918 subtle changes lead to MkII’s being produced. MkII’s were issued with two sets of interchangeable lenses; tinted and clear. Yellow tinting was usually chosen as it was known to filter out ultraviolet light. Triplex produced many military contract pairs and these are marked as such, with a MkI or II prefix to the company logo, but it appears Government Air Ministry factories or other manufacturers also had contracts to produce the type.

Figure 9. Makers marks on the back of the hinge. Left, The yellow furred ‘Yulo’ late WWI – early interwar version. Centre, ‘S.L.M.’ on an interwar leather pair. Some brass framed cloth pairs (right) also have the S.L.M. mark, but most others are unmarked. (N.B. the cloth may be too tightly sewn to see this area).

In the early 1920s when the RAF ‘22c’ stores reference system came into being the ‘MkI Goggle Mask’ was retrospectively given 22c/10 (officially declared obsolete in 1924) and the ‘MkII Goggle Mask’ was given 22c/11 and was issued till stocks ran out. Numbers 22c/33 to 22c/35, were light, medium and dark tinted lenses respectively and 22c/36 were ‘lenses, special’ – prescription lenses for senior pilots.

The original Triplex AB Aeromask and RFC/RAF MkI and early MkII frames were usually made of blackened brass and had a join in the outer radius held together with threaded brazed on lugs and a screw. This join was unscrewed to change the lenses, either for a change of tint or to replace scratched or broken glass. However, the Triplex Featherweight model and most British and Japanese post-WWI non-mask models used Salt’s frame improvement, which had a solid unbroken frame with a simple enlarged lip or ridge on the inner back of the outer radius (Fig. 3 & 20). Albert Edward Salt patented it as ‘Improvements in and relating to Goggles for Airmen, Motorists and Others’ (Pat GB127545), lodged 11th Mar 1919, however, he must have developed the idea shortly after Newbold’s design appeared, as the ‘improvement’ appears on the earliest 1916 ‘Featherweight’ advertisements. With Salt’s improvement the glass was simply placed onto the inner surface of the solid frame and the front wire loop of the sprung cup pushed the glass into place and held it, with the frame lip holding the sprung wire loop in place (Fig. 20); beautifully simple as the wire loop could be deformed with finger pressure for removal and installation of lenses.

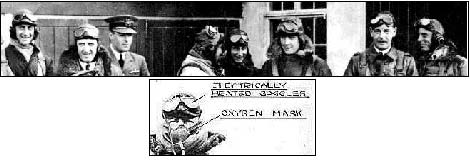

Very robust, with a good field of view, simple to make and relatively lightweight they were very popular. Photos from WWI seem to show them in use by all nationalities, including, what we can assume are captured ones in German use. The RAF did not produce a replacement until about 1933 (the curved plastic lensed MkIII’s), but many pilots used the later version RAF MkII’s (22c/44) well into WWII (Fig. 10 & 15), objecting to the intrinsic distortion caused by curved lenses. It is very difficult to spot the difference between the MkI and MkII Goggle Mask, but in the late 1920s the quite different looking RAF Goggle MkII appeared. These did not have a face mask, were solid ‘Salt’ framed, always had brick-red cloth cups with dark brown fur and had a very distinctive steel-coil-spring tensioned leather strap (see Fig. 10 & 15). Officially they were called ‘Lightweights’ to distinguish them from the ‘Goggle Mask’. They had the stores reference 22c/44, ‘Goggles, lightweight, complete’; 22c/41 were ‘Frames, lightweight’ and 22c/42 ‘Glasses, unsplinterable anti-glare’.

Figure 10. Left, a pair of the interwar version (about 1928-1933) RAF MkII goggles with typical blue tinted lenses (unsplinterable anti-glare?). The broken strap shows three of the four springs used to firmly hold the goggles to the head as mounting speeds increased G-forces. Right, a private purchase pair of MkII’s by D. Lewis. (Note, If mask-less interwar Newbold pattern goggles do not have these sprung leather straps they cannot be called RAF MkII’s).

The Yulo company produced the design during late WWI and into the 1920’s. British companies which are known to have produced versions in the interwar years include S.L.M. and D. Lewis (Figs. 9 & 10) and some of the flat metal containers of unmarked goggles are marked ‘E.I.S.’ and ‘M.B.’. Purveyors such as Dunhill’s department stores sold Triplex and other goggles as private purchase items throughout the First World War and beyond. Triplex did a steady mail order trade via advertisements in various magazines and newspapers, not only aimed at servicemen, but suggesting them to loved ones as practical gifts for men at the front.

U.S. Versions

After its precipitous entry into WWI in April 1917 the United States expedited the equipping and mobilization of her military by adopting several items of proven Allied equipment; most famously the British Brodie helmet. Special Regulations No.41, was issued 15 August 1917, in which it was stipulated that for the Army Air Arm, then part of the Signal Corps, the ‘improved type of Triplex goggles’ would be used by all aviators, motorcycle messengers and chauffeurs; the individual could choose clear or amber coloured Triplex lenses as required. At that time U.S. manufactures were tending to produce typical pre-war goggle types and laminated glass was not officially in production.

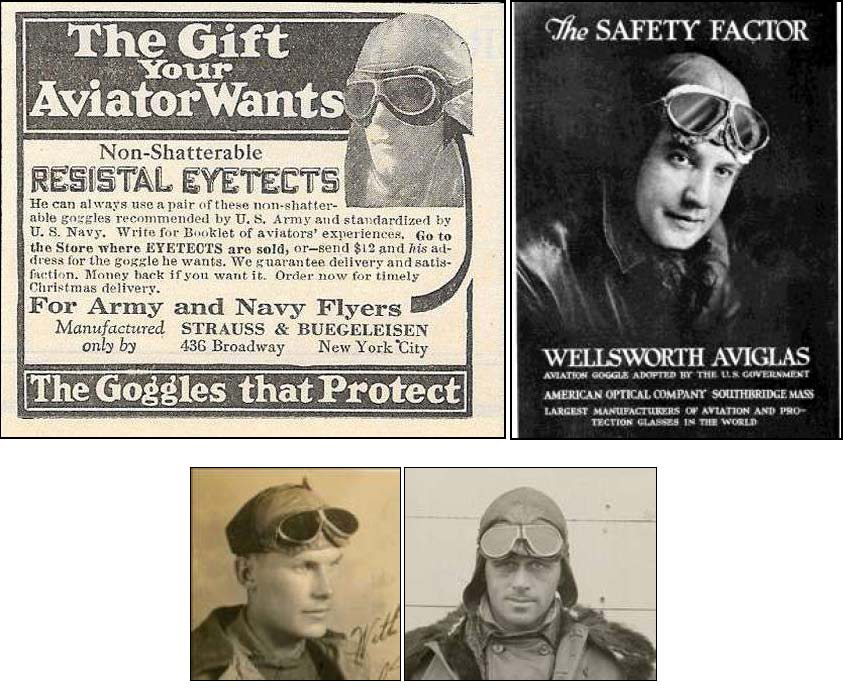

In an understandable effort to achieve self-sufficiency U.S. manufactures immediately began to produce similar goggles to the British Triplex design; as is well documented in the Smithsonian Institution’s collection details. Most notable being the American Optical (Wellsworth Aviglas); H. Buegeleisen (Resistal) and New York Eye Protection (Lamoglas) companies. The Aviglas version seems to have appeared first being patented 22nd Jan. 1918, it used toughened optical, not laminated, glass. It became a private purchase item, and was not adopted by the Government until 1919, perhaps because of the lens material. They came in clear and a yellow ‘Noviol’ (no violet) version. The U.S. Bureau of Standards tested Resistal’s laminated glass ‘Eyetects’ lenses in March and May 1918; leading to their supply to Navy Aviators and, after ophthalmic tests, the ‘new’ Resistal NAK model was recommended to the Army by the U.S. Medical Research Laboratory on 20 Jun. 1918.

These developments may have prompted H. Newbold to lodge a U.S. patent application 15th Jul, 1918, the patent was granted 18th Feb., 1919. The U.S. versions were not identical however, and it is not known if any recompense ever came to Triplex Safety Glass Co. Ltd as a result.

Figure 11. Top left, 1918 Advertisement for Resistal stating that they had been recommended for the Army and standardized by the Navy. Top right, 1919 Advertisment for Aviglas goggles announcing their adoption by the U.S. Government. Bottom Left, U.S. WWI pilot McLaughlin, with Aviglas goggles. Bottom Right Famous Air Mail pilot Wm. Hopson wears Lamoglas goggles in 1925, note large rounder lenses.

Limited numbers of American ‘Newbold types’ got to the Western Front in the last year of the war, with many U.S. aviators having to wear earlier U.S. types (including the pre-Newbold, 1917 ‘Eyetects’ etc), RAF Triplex models or French Meyrowitz-Luxor type goggles etc. They were, however, used extensively as aviation goggles post war and through the 1920’s by both military and civilian pilots (Lindbergh wore Resistal’s across the Atlantic in 1927). They were especially popular amongst the U.S. Air Mail pilots.

Although 1918 Resistal NAK and Aviglas goggles were phased out by the military in the late 1920’s NAK’s could still be bought as private purchase equipment from such vendors as Karl Ort up until 1941. They continued to be popular especially amongst fighter pilots who objected to the distortion caused by the curved glass of the official replacements.

Although the Smithsonian Institution states the American Optical Aviglas version was copied from a British design, they are interesting as they seem to be a highbred of German frame shape, but with a Newbold like hinge; but using long screws rather than pins, a feature carried through on many later AO designs.

Figure 12. Main U.S. ‘Newbold’ versions. Top left. Aviglas, introduced in 1918, famously worn by ‘Billy’ Mitchell. They were made Government issue in 1919, but not using laminated glass were never popular. Top right, Resistal NAK version introduced 1918 and Ok’d for military issue 20th Jun. of that year. Mid. left, NMR version, the same as the NAK, but with a sponge rubber face pad, adopted as the M38 Tank and GP Transport goggle in 1938. Mid. right, The laterally stretched ‘Seymour’ model, introduced in the late 1920’s to address the relatively narrow field of view that was causing curved lens goggles to become popular. Bottom, Lamoglas version with larger diameter lenses than NAK’s, popular aviation goggles during the 1920s.

Figure 13. Left, Charles Lindbergh’s Resistal N.A.K goggles; famous Air Mail pilot and in 1927 the first pilot to cross the Atlantic solo. Left, Newbold goggles worn on Navy-Curtis NC-4 May 1919, first flight across the Atlantic, stopping for ten day in the Azores; one month before Alcock and Brown’s first non-stop flight. Both predating Lindburgh’s solo flight by eight years.

The Salt frame improvement never made it to the States, the lenses and sprung cup fronts were simply held together by small bent tabs on a soft aluminium frame (Fig. 20, right). A raised perforated vent was pressed into the outer radius of the metal frames on most American versions; this can be seen on Resistal, Lamoglas, Wilson and Duplex etc. On British and Japanese versions, the ventilation relied on permeable knitted silk, cotton or linen; or vent holes in less permeable cup materials (close weave cloth, or leather). The British versions often came with an ‘anti-dimming cloth’ to apply an anti-fogging agent to the lenses to counter this perennial problem.

From Air to Armour

In the late 1920’s and early 1930’s the technologies to produce curved laminated and toughened glass; and non-flammable; scratch resistant bendable plastics were perfected. With the increased field of view possible with curved lenses ‘Newbolds’ and other flat glass goggles became less common in the air. (Although by mid-WWII flat lenses were back as split lens RAF Mk IV to VIII (still available today) and plastic U.S. B8 (the ancestor of most modern tactical goggles) etc, due to the intrinsic distortion caused by curved lenses).

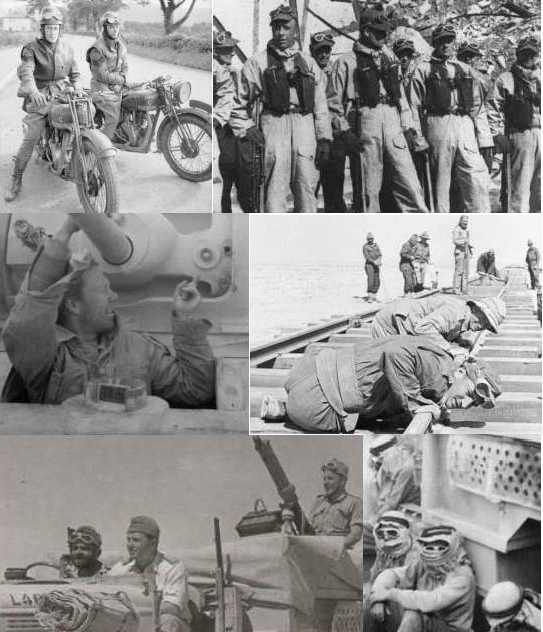

Although generally retired from the air, in 1930 the Japanese ‘Newbolds’ were modified and adopted as the IJA’s official Tank Goggles. In Britain at about the same time a grey version of the venerable ‘Featherweight’ became the standard ‘General Purpose’ Tank, Transport and Dispatch Rider goggle.

In 1938 the Resistal N.M.R. version (with a sponge rubber face pad) was adopted by the U.S. Army as the M38 tank and motorcycle goggle. With lend-lease etc. it became a widely worn piece of Allied equipment. M38s can be identified by always having the rubber face pad covering the rear hinge area, (if this area is open it is the cheaper commercial R.A.V. model); M38s were never fur lined. Military issue Resistals tended to have unmarked, leather or leatherette tags; good quality gold embossed leather tags are probably pre-war commercial examples and completely metal strap attachment points, pinched to the wire frame, are probably post-war. The frames were always marked ‘Resistal, H.B. NY’ (Harry Buegeleisen Co. New York) on the top of both frames.

Figure 14. Top Twelve years on from their introduction Goggle Masks still being worn at RAF Kenley in 1928. Bottom, rare British 1920s research and development.

In Britain funding for equipment development was severely curtailed after WWI, practically ceasing for more than ten years. Hence the RAF MkII Goggle Mask was produced unchanged until about 1930. The fate of the ‘Featherweight’ model name is not known after the first Triplex Co., ceased trading as such in the early 1920’s, but this simple mask-less; solid frame design; with conventional elastic straps continued to be produced as aviation and driving goggles (see Sir Donald Campbell’s 1931 pair, Fig 24). From about 1928 to 1933 a re-modelled RAF MkII (the 22c/44 as mentioned above) was produced to meet the demands of flying in enclosed cockpits in the faster and more acrobatic planes of the time.

It appears that with the introduction of the plastic lensed RAF MkIII in about 1933, RAF manufacture of ‘Newbolds’ ended and the tooling was then used solely to produce ‘General Purpose Goggles’(GP) for the British and Commonwealth armed forces and the civilian market. These were very similar to the original ‘Featherweight’ model of 1916, but were alloy or brass and then nickel-alloy ‘white metal’ frames rather than the blackened brass of the AB Aeromask and did not have the early hooked strap (Fig. 1). Early black and white images of the Featherweight seem to show they were always a darker colour than the later light-grey GP ones (Fig. 7 top right); the early Featherweight examples shown in Fig. 6 are dark-earth-green or chocolate brown.

Figure 15. First three; pictures of the remodeled ~1928-1933 RAF MkII’s still in use in WWII, top left, pilots in the Middle East. Top right and bottom left, Battle of Britain Pilots. Bottom right ‘Blotto’ of RAF 55 Bomber Squadron, Iraq 1930s.

Two types of British ‘Newbold’ GP goggles were available; grey cloth cups and fur, or perforated brown leather cups; both cup types had simple two piece interlocking grey elastic straps. The straps on both versions were all elastic on pre-war examples, but from about 1941 they were half cloth and half elastic to save on rubber. Both strap versions had identical two plain metal slider adjustment (See Fig.21), (the same as the original Goggle Masks, (see centre Fig. 5)). The grey cloth cupped version tended to have clear or yellow tinted glass, the leather versions usually had orange glass, but there are clear lens examples.

Figure 16. Indian soldier in N. African with ‘Featherweight’ goggles?, note dark cloth and velvet edged tags.

Probably for economy reasons in the early war years the British started to produce a simpler round goggle (Fig. 18 & 21), (copied from WWI DR goggles; Triplex ‘A’s?) with identical grey cloth material and fur to the GP ‘Newbold type’. These simple round GP goggles appear to have been issued alongside the ‘Newbold types’; whether this was using up old ‘Newbold’ stock or military manufacture of the ‘Newbold’s’ continued is unclear.

Early; before about 1942, grey cloth and fur British GP goggles (Newbold type and early round lens) appear to have been issued unfolded laying in sheet metal rectangular hinged cases (like a big school geometry set), or later in plain brown cardboard boxes of the same dimensions. Commercial versions were in proprietary labelled boxes. The leather cupped version came folded in better quality squarer rectangular, orangey brown, textured leatherette boxes. These were held together with distinctive large textile studs on their sides. With the difference in quality and cases it can be speculated that the grey fabric cupped goggles may have been produced for the rank and file and the leather ones for officers and commercial sale.

Figure 17. British light grey ‘General Purpose Goggles’ in many roles during early WWII. Top left, BEF dispatch riders, France 1940. Top right, Canadian ski troops. Middle left, ‘Matilda’ driver pointing out AP bullet crater in gun mantle. Middle right, Engineer, track lying. Bottom left, Long Range Desert Group, travelling and bottom right, sheltering in a sandstorm; the need for goggles is obvious.

Figure 18. France 1944, a Bren Gun Carrier crew wearing the British wartime economy round GP goggles and a pair of U.S. M38’s.

Figure 19. The Resistal N.M.R model was adopted by the U.S. Government in 1938, and under contract produced as the M38. Top left, a pair of M38 goggles on an M38 US Tanker helmet. Top centre, US Grant tank driver. Top right, a US aviator wearing M38’s or private purchase N.M.R’s. Bottom left, a French Tanker and bottom centre and right, British Dispatch Riders.

Figure 20. Left, two images showing how the British version (same on Japanese) had the ‘Salt improvement’ of a lip on the outer radius into which the sprung front cup loop expanded holding the lens in place. Lens replacement simply involved figure pressure (!warning doing this to 70-100 year old cloth or leather will probably destroy the material!). Right, Resistal and other U.S. versions had small bent tabs. These will crack or break if re-bent, making lens replacement risky even on new goggles.

Figure 21. Relative dating of British General Purpose Goggles. In both images the top goggle is an early WWII example (tin case marked E.I.S. 41); the two piece overlapping strap is all elastic and the leather tabs are edged in velvet, (as was the 1916 Featherweight, Fig.1 & 6). The lower goggles are wartime manufacture. One of the two straps is now cotton (herring bone weave), saving rubber stocks, and the tabs are plain. The two slider adjustment can be seen; the same as the WWI Goggle Mask (see Fig. 5, center). The rounder profile of the brass or alloy frame of the earlier model (top left) can be seen, the more anglar and thinner ‘white metal’ frame can be seen on the later one (left bottom). On the right the similarity in materials used in the ‘economy Newbold’ (center) and the even cheaper round GP goggles at (bottom) can be seen.

The Japanese Versions

The Imperial Japanese Navy (IJN) invited the British Aviation Mission (BAM) to Japan in 1921, it was made up of 30 RAF instructors and staff led by (the later infamous) Colonel Sempill. The 18 month mission went well and in 1923 the IJN procured quantities of RAF gear. It appears that amongst this equipment were solid frame ‘Featherweight’ goggles. These were copied almost exactly, and from 1925 were produced in Japan and became the standard IJN aviation goggle.

Figure 22. Japanese Newbold’s. Top, Used as IJN aviation goggles, produced from 1925 to around 1929 and still in use in training establishments during the 1930’s. Bottom, A version of the design was the standard Tank Goggle from December 1930 to 1945.

Between 1927 and 1929 tests were undertaken comparing these goggles with examples from the U.S., Canada, France and Germany. The report (translated and provided by Nick Komiya) concluded – ‘The dominance of Triplex designs as a World standard has already ended in the Western world, the new standard against which we will need to define and measure ours is the Luxor type (in use in the U.S.)’. The report listed shortcomings in the ‘Triplex’ design as; a narrow field of view; a tendency to fog; and during accidents cases of the hinge causing injuries. As such other designs, both local and foreign, were tried and tested from 1929 on, culminating in 1937 in the IJA’s Colonel Goto’s famous ‘Eagle Eye’ design ( aka ‘Cats Eye’) being adopted by the Navy. The actual date of official phasing out of the Newbold type by the IJN is not known, but photographic evidence seems to show they continued to be used in training establishment and by individuals during the 1930’s. Apparently Takashimaya, a department store, marketed private purchase standard, and split frame goggle-mask, versions until early WWII.

The main difference between British and Japanese versions is that the British two piece overlapping strap was sewn into the leather tags, the Japanese version had metal loops on the tags onto which the two piece elastic strap was sewn; similar to U.S. models except the single piece U.S. strap was threaded through the loops and then through sliders which held them in place, (note, no part of the U.S. strap was sewn). Apparently the IJN versions retained the early ‘Featherweight’ colours of mid-brown and mid-green cloth. The cushion material was of fur, but often had very distinctive thick rim pads of soft brown leather or velvet.

Figure 23. Japanese Tank Glasses, with distinctive leather cushions and strap sewn to metal loops on leather tabs (note, yellow lenses were not standard). Right, distinctive single thickness loose weave linen for ventilation, (note, most other Newbold versions had the cloth folded over the sprung wire frames forming an envelope of double thickness).

As mentioned above the aviation goggles were Japanese Navy issue during the late 1920’s, until curved glass designs started to take over. But just like in Britain and the United States the Japanese ‘Newbold’s’ were then redesigned and produced as tank goggles. Introduced as such on 8th December 1930 and officially designated ‘Sensha Megane’ (Tank Glasses). They were produced by a number of manufacturers including Yamatatsu Ltd and the Ishihara Factory. They differed from the British, U.S. and IJN versions in having a single layer of loose weave, un-dyed linen making up the cups, and soft brown leather or suede cushions. Specifications called for clear laminated glass, but tinted versions are found, which may be replacement lenses, many Commonwealth goggles and spares would have fallen into Japanese hands in 1941-42. The type was produced until military production ceased in, or before 1945.

Unlike the ‘General Purpose’ British ‘Newbold’ goggles and U.S. M38s, the Japanese version seems to have been exclusively used by tank crews. Other transport personnel, or troops in dusty environments wore other goggle types such as leather/leatherette, folding lens goggles (based on very early WWI French designs and similar to those used by Cold War China and USSR until the 1970s), etc.

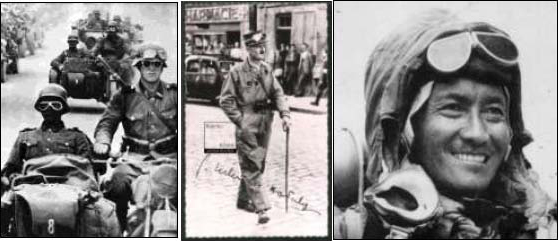

Figure 24. Famous faces. Top left, Sir Alan Cobham, early 1920’s aviation pioneer, in Goggle Mask. Top center, 1927 Charles Lindbergh with Resistal N.A.K (D.G) model (D.G. had double thick fur). Top right, Amy Johnson 1930 with a Goggle Mask. Bottom left, Sir Donald Campbell in 1931, with the standard British ‘Featherweight’ or early GP variety, (note felt edged leather strap tag). Bottom centre, Emilia Earhart, with plain Resistal N.A.K’s. Bottom right, Artist’s rendering of Howard Hughes wearing hinged goggles on the front cover of a gossip magazine. Will he marry Katharine Hepburn?

Figure 25. Newbold’s with other nations. Left, June 1941, unable to defeat the RAF, Germany turns to the East with Operation Barbarossa, here, entering Russia the sidecar passenger has British goggles, probably left behind in France by the BEF. Center, General Leclerc, Commander of the French 2nd Armour Division takes a stroll through Paris, August 1944, sporting British GP goggles. Right, 1953, Tenzig Norgey, after the ascent of Everest (note, for the ascent he had worn oval Austrian mountaineering goggles).

End of Military Production

Late to post WWII for general purpose use the U.S. and British military went over to cheaper or better goggles, such as the British round GP type, or the U.S. plastic single lens Polaroid 1021; officially listed as M44 (Army) or B8 (Air force). The U.S. aviator AN-6530 goggles were used by U.S. armour crews if available. Post war photographic evidence shows that alongside the round GP goggles and M44s, the split lens RAF Mk VIII became popular with British tank crews.

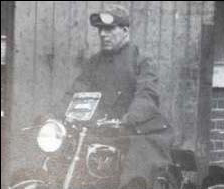

Although military production and issue appears to have ended in the late war years, Harry Newbold’s 1916 design, ‘soldiered on’ in the UK until at least the 1960’s as civilian motorcyclist’s goggles and in the States as civilian Resistal N.A.K’s, N.M.R’s and Seymour models and Triplex Safety Glass Co. of North America versions. These were sometimes tagged with motorcycle manufactures names for the ‘sectarian biker’ market.

Figure 26. Although the type had many ‘finest hours’. They also protected the eyes of several generations of working people on their way to and from work, before afforable family cars appeared.

Figure 27. Top. Harley Davidson tagged goggles (US Triplex? note protruding doorhinge like link) and a pre-war rider. Bottom, European competition riders, pre and post war.

Figure 28. Left, WWII Canadian designed and made transport goggles. Very similar to Newbold’s, but have a sprung steel strip at the bridge, rather than a hinge. Right, Retlaw 2120 model. Another hinged design, similar to ‘Newbold’s’ design, but less robust.

Figure 29. An unusual pair with split frames clamped with a hinged radius piece. The origin of these is obscure. Although being sold as ‘Pacific U.S. aviator goggles’ no referrences to such goggles can be found. The colour and the way the hooked elestic strap is sewn into the leather tags would hint at an early British origin? Although such radius piece clamps were often seen on various French goggles?

Conclusions.

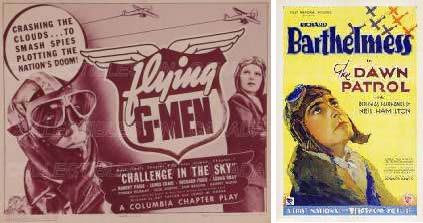

It appears this familiar goggle type, versions of which graced the faces of numerous military and civilian pilots; drivers, racers and actors, both famous and mundane up to the mid twentieth century and beyond, can trace their roots back to early 1916. At that time the London based Triplex Safety Glass Co. Ltd designed and offered them for sale after recognizing a need for stronger goggles on the Western Front. They were immediately popular with military airmen because such a robust type was needed to replace the elegant, but small and flimsy Edwardian driving goggles then in use. The Edwardian goggles had been fine on flights of low altitude, minutes rather than hours long and speeds rarely topping 80 mph, but they were prone to be uncomfortable and fall apart when war time operations became hours long, fast and aerobatic. In contrast to the typical pre-war goggles a pair of ‘Newbold’s’ had a wider field of view; could be sat-on and still be of use; hit by small shrapnel or traumatically impacted against dash boards and not automatically blind or disfigure the wearer; a quality used often in Triplex’s advertising (e.g. Fig. 1) and later by Resistal. They were reasonably easy and cheap to make and their simple hinge was pioneering, offering more structural strength, stability and comfort than the other fledgling robust types. Its main rival in the professional aviation world was the more delicate and expensive Meyrowitz/Luxor type, which had an adjustable bridge like hinge. The next generation of quality curved lens aviation goggles in the 1930s and 40s had various designs of flexible or adjustable hinge, all building on Harry Newbold’s inspiration.

Within months of Harry Newbold’s design being offered by Triplex they were adopted by the Royal Flying Corps and Royal Naval Air Service, (soon to be amalgamated as the RAF) as official issue. They were then assured of being distributed widely to Allied personnel; both regular and volunteer. Soon they were being copied in several countries and in the interwar years became an everyday part of aviation, driving and riding life. The type was so common their origins were forgotten and today confusion seems to reign when people try to indentify a pair, with their own interests or experience often colouring their views of the type’s origin. The confusion is not helped by the early history of the Triplex name, which was owned by various companies in several countries through time. As outlined above, the confusion around the Triplex name and the large number of versions made by other companies over more than half a century is why here it is suggested that unless the exact make and model type is known, it should perhaps be generically called a ‘Newbold type’.

Oscer winning movie ‘Wings’, 1926. Left, wearing an uknown Newbold model? no frame vent, but U.S. style unsewn straps held by sliders. Right, Resistal N.A.K model, notice top half of the leneses are tinted.

Inexplicably, Donald Sutherland wore British all leather ‘Newbold’ goggles in ‘Kelly’s Heroes’ (1970)

Steve Saunders

October 2015

Acknowledgements

‘The Association for the History of Glass’, especially John Clark helped greatly in working out the early history of the Triplex companies.

Nick Komiya of the http://www.wehrmacht-awards.com forum, for detailed information on the Japanese versions.

(The 1931 Nicholas Beazley catalogue available as a pdf at www.dmairfield.org is a good source for identifying the different Newbold type goggles on offer by Resistal and others at that time).

Are there replacement lenses for these goggles. Thanks

no,i made my own .using old casstte tapes case glass.

Hello, I am from the Czech Republic and maybe interesting glasses similar to those of your web site. Please email me at 133ps@centrum.cz and I will send a photo. Thank you. Luděk Meitner

Hi, I come across this site while researching a pair of British Newbold goggles I acquired. They are in a sheet metal tin as described in the article. The tin is dated 1939 and is manufactured by F Francis and Sons, London. The design of the goggles is as described above and appear to be correct for the era. If you like you can contact me and I will provide photos.

Hi Michael,

Nice find. The name on the tin ‘F. Francis and Sons, London’ is actually the makers of the tin case! Several other manufactures names can be found on the cases including ‘MB’ (Metal Box Company, Mansfield). Unfortunately the name on the case is nothing to do with the manufactures of the goggles, the same cases were also used for Bren gun parts! etc.

The date on the case however, does probably correspond to the date of the goggles as the cases were probably brought into the goggle factory and the goggles placed into the case before sending out to recipient?

SLM (S. Lewis) goggles seem to have used MB cases, especially for their little WWII dust goggles.

All the best

Steve