A Canadian World War II era pressed fiber helmet. While it was against regulations many regiments issued these helmets with cap badges. This example features a 21st Battalion, Canadian Expeditionary Corps cap badge. (Collection of the Author)

While little has been written about the American pressed fiber sun helmet, even less has been written about the versions used by Canada. According to our friend and colleague Clive Law the Canadian Army acquired the “fibre” helmets prior to the outbreak of the Second World War for summer training as a substitute for the more expensive and fragile Wolseley helmet.

The chosen supplier was the United States based manufacturer Hawley Inc., which also supplied the pressed fiber sun helmets to the United States Marine Corps, United States Army and United States Navy. The demand from Canada was apparently so great that a Canadian factory was set up.

What is also notable is that there appears to be two distinct patterns. It is likely that the original helmets used came from Hawley in the United States and production was then set up in Canada. The first pattern seems to be a version that has three grommet holes on each side – two to hold the liner in place and a third for the chinstrap. These holes doubled in variation.

An early Hawley pressed fiber sun helmet with original chinstrap. This pattern helmet may have been made in the United States for export. It is does not feature a grommet on the front, but examples with Canadian and even Argentinean badges are common. (Collection of the Author)

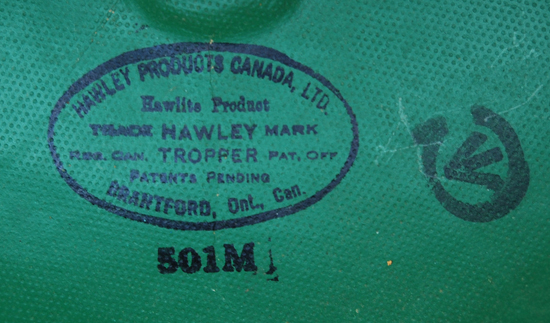

A second version with nine grommets per side was likely produced exclusively in Canada and only worn by Canadian troops. These helmets were produced in Brantford, Ontario by “Hawley Products Canada, Ltd.”

The “classic” Canadian made version of the pressed fiber (fibre) sun helmet. This helmet features three sets of grommets on each side – a total of nine vent holes. This example above was painted a brown – possibly to match a uniform. (Collection of the Author)

The profile of the Hawley Products Canada, Ltd pattern helmet. It shows that the helmet featured a faux three-fold puggaree, which was the number of folds in the British-produced Wolseley helmet of the era. Unlike the American designed helmets these offered three sets of vents on each fold of the faux puggaree (Private Collection)

A third variety exists but these helmets were based on the South African style “polo” sun helmet. These helmets featured the profile of the “polo” helmet and are the only pressed fiber helmets made by the United States or Canada to feature an actual vent cap at the top.These helmets were also produced in Brantford, Ontario.

Some of the South African style “fibre” helmets were reportedly used by Canadian troops.

The Hawley Canada helmet that was produced for export to South Africa. It features the four vent holes that mirror the vents on the South African produced “polo” sun helmets as well as three grommets for the liner, and there are three more grommets on the rear visor that are in the same place as the holes in the South African used British MkII steel helmets. (Collection of the Author)

The “Fibre” helmets were never worn overseas but were a staple headdress during training for troops in Canada and these remained in use for a brief period after the end of the Second World War. Although prohibited by regulations a number of units added flashes, puggarees and other embellishments.

A “fibre” helmet with the badge for the Le Régiment de Maisonneuve (The Montreal Regiment). (Collection of the Author)

Another helmet featuring the badge of the Canadian Infantry Corps. This example is unique in that it appears to be manufactured of a pressed fiber of cork. (Collection of the Author)

Liner Versions

The liner of the first pattern Canadian pressed fiber/fibre sun helmet. As noted it features three grommets/holes on each side. Two of the grommets hold the liner band in place while the third grommet is how the chinstrap is attached to the helmet. (Collection of the Author)

A view of the liner in the Brantford produced helmet. Two grommets on each side also hold the liner in place, while the third is for the chinstrap. In addition there six vent holes on each side. (Collection of the Author)

The “cork” example. It features an unfinished interior that shows exposed fiber cork. This helmet also features a unique headband with extra vents in the leather. (Collection of the Author)

The liner in the Brantford produced helmet for the South Africans. It features a much more robust liner – possibly because this helmet was intended to be actually used in tropical climates including North Africa. It also features a chinstrap loop instead of a fixed chinstrap, and this is the only pattern pressed fiber helmet to feature an actual ventilator at the dome of the helmet. (Collection of the Author)

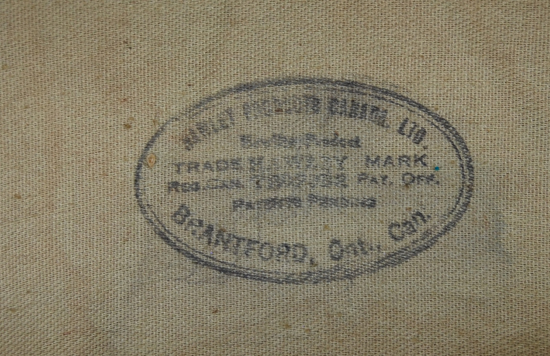

Stamps

The Canadian military “broad arrow” stamp. This stamp appears in many of the helmets that feature three grommets on each side. This may suggest that these were produced in the United States for use by the Canadians. (Collection of the Author)

The Hawley Products Canada stamp in the South Africa export pressed fiber helmet. (Collection of the Author)

Peter Suciu

September 2014

I have a Hawley with ‘Naval 13’ branded into the leather head band.

– the after brim is more squared off like a Wolseley

– there is a cruciform ridge dividing the dome into 4 segments

— where the ridges intersect at the top there is a faux ventilation cap, with a loose perforated light metal disk at the top of the interior of the helmet for screwing down the threaded post of the ventilation cap.

– there are 3 vent holes on each side all in a line, not triangular

— 2 for the head band supports

— 1 for the leather chin strap attachment

I have a Hawley example in unfinished Cork as well. Sadly, there is no regimental cap badge or other identifying marks. Do you perhaps know which Canadian units were issued these sun helmets, or in which theatres they were used? I had (incorrectly) presumed that this was of Boer War or WWI vintage, so thank you for the correction!

Many of the Canadian sun helmets, manufactured from kraft paper and cork dust bonded with urea formaldehyde, were made in the late 1940s and early 1950s, were produced by E.H. Shuttleworth and Sons, Commissioners’ Road, London, ON.

South African troops started World War II wearing the polo helmets in the Abyssinian Campaign (1940-41) but there is clear documentary evidence that at some stage they started wearing the Canadian fibre helmet you have illustrated, presumably because they ran out of stocks of the originals and it made more sense to buy the Canadian type rather than make them locally’

This is a reasonable bit of speculation because the South Africans were heavily involved in more pressing war industries. It is not generally realised that in addition to supplying combat troops the South Africans turned out enormous quantities of such items as Brodie-pattern steel helmets, boots, blankets, mortar bombs, artillery shells and so on, not just for themselves but also the British and Commonwealth forces. Among other things they built a batch of 3.7-inch howitzers for the Indian Army and a great number of locally designed armoured cars, built on Ford or Chevolret three-tonner chassis with imported Marmon-Herrington four-wheel drive trains (the British bought more than 1 000 for themselves for use in the Western Desert). But I digress. The Canadian helmets, which saw service alongside the older polo helmets as they were replaced piecemal, were apparently well-liked, the troops’ only complaint being that when the wind came from certain directions it made a most annoying whistle as it passed through the ventilation holes! The sun helmets went out of active-service use when the South Africans went on to fight in the Italian Campaign, but after the war the helmets stayed on, mainly for ceremonial use,for a number of years. Up to 1943, though the polo helmentand its replacement were a South African trademark (along with brown boots, the rest of the Commonwealh wearing black), just like the “digger hat” of the Australians and the “lemon-squeezers” of the New Zealanders. I still have the polo helmet worn by my father in Abyssinia and the desert, and a late model of the Canadian helmet.

There is a decided anomaly in the first photo in this article. The 21st Battalion was a World War One unit (as were all of the numbered battalions of the Canadian Expeditionary Force raised specifically for that conflict) and was disbanded in 1920, long before WWII. The badge is presumably a late “add on” …

The distinctive cork interior of the E.H. Shuttleworth Moulded Products sun helmet originated with the cork dust packing of grapes and exotic fruit imported by Ed Shuttleworth’s father, a London, Ontario, fruit wholesaler. This surplus packing material inspired Ed to devise a method of bonding the waste cork with urea formaldehyde. It was then sprayed into a mould already lined with a thin textile and kraft paper. The basic shape was modelled on a sun helmet produced for the Chicago World’s Fair (1933-34). Ed received a cost plus contract to supply the Canadian army with his tropical helmets during the Second World War. About a quarter million were produced. They were later used by the Canadian army cadets into the 1950s. After the war the helmets were sold in the United States and in New Zealand for civilian use. This information is based on personal interviews with Ed before his death in 1972 and with his son Ted.